Over-Powder Thermal Transfer Drying Rewinding Exhausting DTF Powder Shaking Machine

Product Description

Cowint brand white ink heat transfer powder shaker, extended white ink heat transfer powder shaker, the length of the powder shaker is 2.58 meters, the oven part is 1 meter, 8 800W high-power heating tubes, and both top and bottom are equipped with high-grade reflective stainless steel Mirror surface, the temperature in the furnace is more balanced and uniform, and the highest speed printing mode of the four-nozzle white ink heat press machine can reach 40~50 square meters / hour, and it can still be dried at low temperature for a long time. It can dry thoroughly, evenly, and the product is stable.

Product parameters

product name | powder shaker machine |

drying time | 15 seconds to map |

Voltage | Rated voltage 220V, rated current 30A, rated power 5.22KW, energy consumption 2-3.5KW |

Retractable media width | 0-600mm |

Machine size | 1930*1120*1136mm |

Package dimensions | 1985*1090*1080mm |

Weight | 260KG |

powder control | Powder shaking control, dusting control, direction, amount control |

Control method | semi-automatic |

Applicable media | Nylon chemical fiber, cotton, leather, swimwear, wetsuit, PVC, EVA, etc. |

transfer method | Mesh belt transmission, belt guide type, automatic induction winding and winding function |

Shipping time | Shipping: January to February Air Freight: 1 week |

Feature

1.The fuselage is made of 1.3-meter sheet metal metal material, which is not easy to rust and has a long service life

2.Solid and durable, almost fully enclosed, good mute, the powder shaker cover

3.Independent temperature control, easy to operate

4.The powder shaking speed is controllable and the powder shaking is even

5. Mesh belt conveying, the thermal transfer film does not deviate

FAQ

Welcome to send a message to my mailbox to consult your doubts, we will provide you with a one-stop sales service process

Why does the hot melt powder fall off the mucous membrane?

Why does the heat transfer film burst as soon as it is pulled?

Is the blistering of the heat transfer film related to the hot melt powder? Is high elasticity hot melt powder good?

What is the reason why the white ink heat press machine does not shake the powder cleanly?

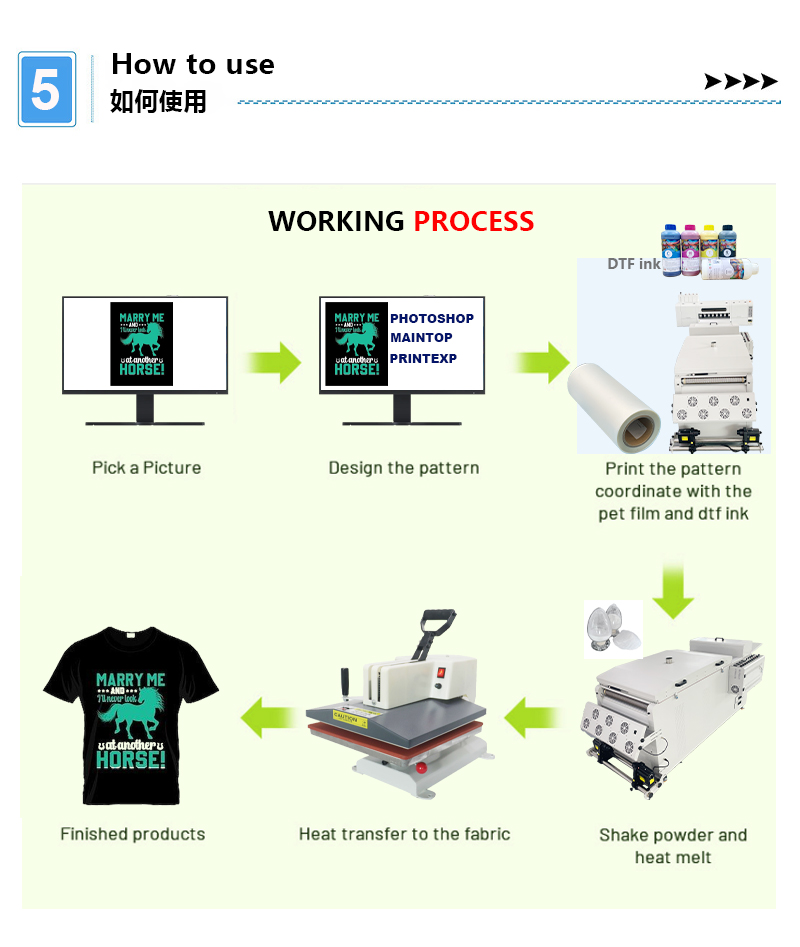

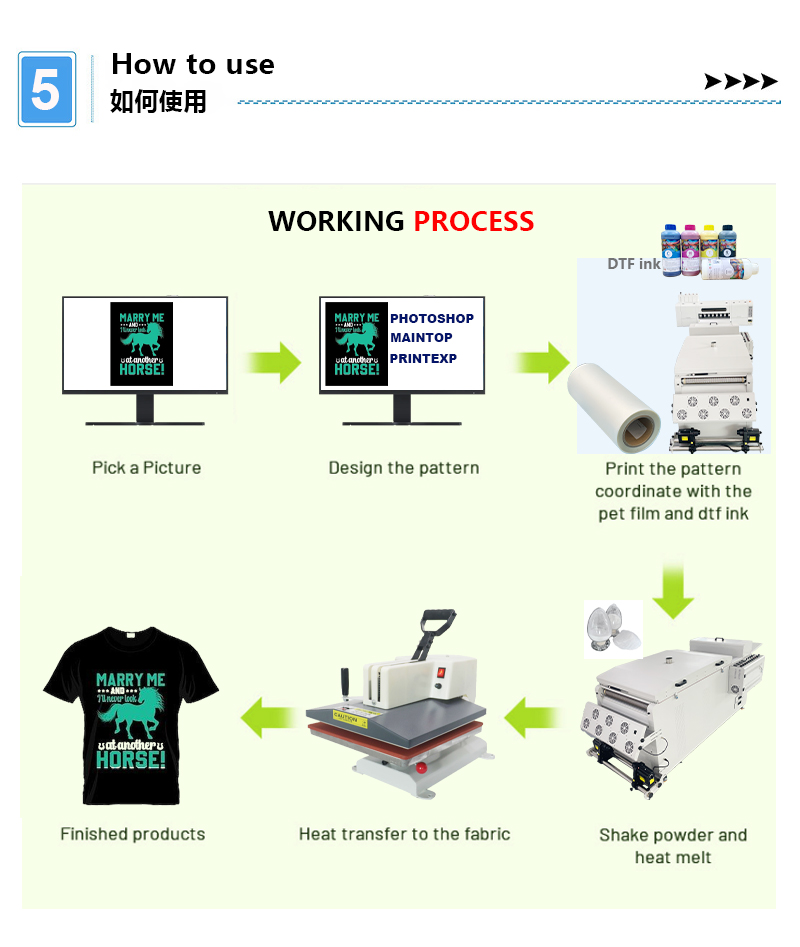

How to use the white ink heat press machine?

+8615820889696

+8615820889696 Info@cowint.com

Info@cowint.com